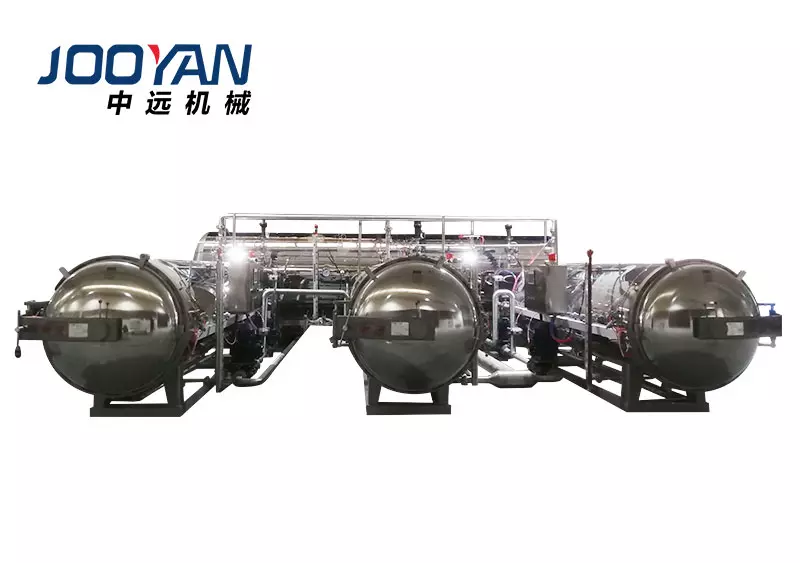

The sterilizer consists of a pot bottom, a lid, an opening device, a locking wedge, a safety locking device, a track, a sterilization basket, a steam nozzle and several pipe ports. The lid is sealed with inflatable silicone rubber, which is reliable and durable, and has a long service life. It has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time, and easy control of heating temperature. So, sterilizer manufacturers: what are the main uses of sterilizers?

Sterilizer manufacturers: what are the main uses of sterilizers?

Uses of sterilized cookware: Sterilized cookware is widely used in the food and pharmaceutical sectors. High-temperature sterilization is especially subdivided into food, eggs, seafood, fresh corn, wild vegetables, soy products, aquatic products, canned products, packaging bags, beverages, dairy products, and other foods such as meat, eggs, fresh corn, wild vegetables, and cream products.

Food is essential to people's lives. Therefore, the competition in the food industry is also fierce. High-temperature sterilized cookware is specifically used in food products. After sterilization, food can ensure that people eat it healthily. Sterilization cookware is divided into two types based on the material: carbon steel and stainless steel. Stainless steel is usually used. Most edible mushrooms are cultivated using carbon steel.

3. Complete the document. Customers do not need to install the equipment after purchasing it, and the company will send professional technicians to install and debug it.

Sterilizer manufacturers: what are the application features of sterilizers?

Sterilization cookware is widely used in food, medical and various high-temperature materials. For example, PP bottles, aluminum foil bags, high-temperature transparent plastic bags, and high-temperature boiling bags. The lid is equipped with a rubber sealing ring to reduce energy consumption, prevent leakage, and have a long service life.

2. Sterilization cookware can be sterilized at high temperature in a short time, significantly reducing the temperature of traditional fungus cookware and fundamentally improving efficiency. The process water used in the sterilization process cannot be used once, but can be used multiple times, saving energy to a certain extent, greatly reducing production and manufacturing costs, and improving profits. During the disinfection process, the process water will continue to flow from multiple angles to prevent sterilization dead ends, and the product quality is guaranteed, so you can use it with confidence.

3. Sterilization adopts fully automatic control mode and intelligent temperature control. For larger products, heat penetration can be achieved to ensure sterilization effect. In addition, the entire sterilization process will run automatically according to preset steps, which can prevent errors during operation.

Sterilizer manufacturers: How to use autoclaves correctly?

Method/Step 1. Add water, close the drain valve, adjust the main valve to the word "good", open the water inlet valve, inject distilled water into the steam generator, when the water level is about 1 to 2CM, close the water inlet valve, then close the water inlet valve, then close the water inlet valve, then close the water inlet valve, and then close the water inlet valve. Instead of the main valve for "closed".

2. Place the pot and place the items to be sterilized into it. Be careful not to put it too tightly. Triangular flasks and tubes should be placed flat or at an angle to prevent contamination of the culture wool during sterilization.

3. Close the door, turn the handle clockwise to enter the block into the knocker, and then move the octagonal turntable to make the door tight and the gasket fit tightly.

4. Turn on the power and turn the power control switch knob to the "on" position. The power indicator is on, indicating that it is started. At this time, the electric heating indicator light is on, indicating that heating has started.

When inspecting insulation, if the steam inside the jacket heats up to the automatic control pressure, the electric heating indicator will go out in vain, indicating that the heating has stopped. As the heat sink pressure drops, the electric heating indicator light lights up, indicating that the heating continues, indicating that the controller is working normally. When the steam inside the sleeve is heated to the selected control pressure, the steam inside the sleeve can be directed into the sterilization chamber for sterilization.

6. After the sterilization is completed, immediately cut off the power supply according to the nature and requirements of the sterilization project to determine whether the steam in the disinfection room is naturally cooled or slowly discharged. If a sudden drop in pressure affects these items, the main valve can be directly adjusted to the "slow discharge" to quickly discharge the indoor steam from the disinfection chamber. When the pressure in the disinfection chamber drops to "0", open the door by the handle 5 to 10 cm and remove the sterilized item after 20 to 30 minutes. At present, the sterilization project is relatively dry.