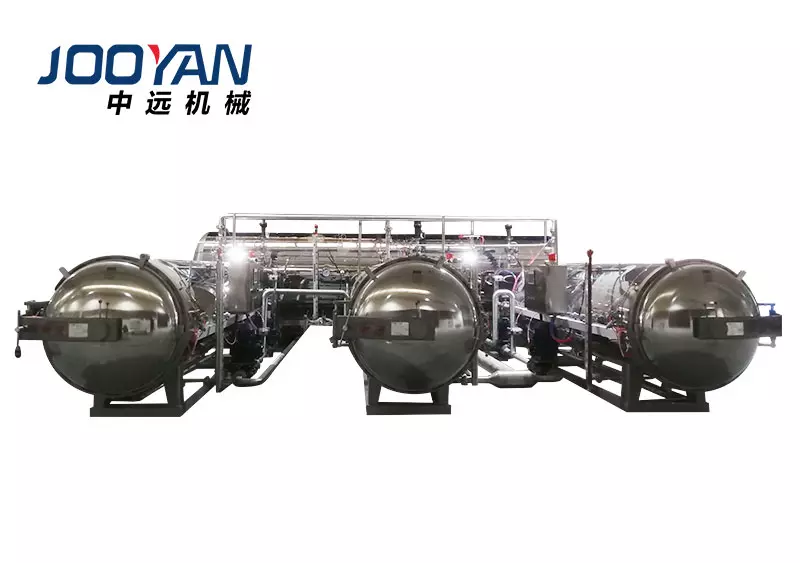

During the cycle, the sterilizer manufacturer used three to ensure uniform water outlet in the pot. Point-in series. The circular water switch accessory can be quickly heated through the steam switch accessory (using this steam exchange accessory to avoid direct contact between steam and goods during heating in the pot, so as to keep the temperature of some goods very high) (there are two points at the top, bottom, left and right), allowing hot water to directly reach the sterilization cookware for circulation. When circulating the hot water in the pot, the steam Angle valve automatically opens to suit the temperature in the pot.

At this point, the temperature in the pot is accurately transported to the temperature control instrument through the temperature transmitter to control the steam Angle valve for temperature regulation. According to the rise and fall of the temperature in the pot, this regulating valve is gradually adjusted to prevent the pot from reaching the temperature. When the set temperature is reached, close the steam Angle valve and enter the product sterilization stage (the sterilization time for different products can be adjusted). When the sterilization time is reached, the alarm sounds. Open the water outlet valve and start the pump. Send the water pump in the pot to the hot water pump to the hot water pool, and then circulate to the next sterilizer.

3. When the product enters the cooling stage, turn on the pump and then transport the cold water to the pot. It stops when the water level is set, and then opens the disc to circulate the cold water in the pot to lower the product temperature. If the working time is long, when the cold water in the pot does not cool down, open the overflow valve to discharge the hot water at the top inside the pot, and then let in other cold water to achieve the purpose of cooling.

4. The pressure in the pot is transmitted by the pressure transmitter with the pressure of the pot and the signal is sent to the pressure controller to automatically correct the pressure in the pot, so the pressure in the pot is always within the specified range. If it is exceeded, it can stop automatically. If it drops, it can be protected automatically. Disinfect the pot in the pot under the same pressure.

5. After reaching the cooling temperature in the pot and solidifying, the cold water in the pot is discharged, the pressure in the pot is removed, and the sterilization is completed. The operator opens the chain device to open the pot door and pick up the goods.