{{ variable.name }}

I. Pre processing system 1. Feed elevator

1. Feed elevator

Function: Elevate raw materials to the stone removal cleaning machine

Mesh belt: 600mmW, heavy-duty rubber belt

Power: 1.5KW

2. Three in one stone removal cleaning machine

Function: Remove impurities such as sand and gravel from raw materials; And perform surface cleaning to prepare for peeling. Three section integrated design, saving 1/3 of water compared to conventional equipment

Size: 5090 * 1450 * 2700

Production capacity: 6T/H

Power: 7.7KW

3. Platform

Function: Equipped with guardrails and ladders for cleaning and maintaining equipment

Frame material: 50 * 50 * 2mm square tube+crocodile plate SUS304

II. Peeling system 1. Feed elevator

1. Feed elevator

Function: Heavy duty hoist, wear-resistant rubber conveyor belt, suitable for high load and long-term operation, lifting products to the peeling machine

Size: 4200 * 1200 * 5600

Power: 3KW

2. Automatic weighing and feeding system

Function: Cache potatoes, equipped with a weighing system and automatic control of the feeding elevator start and stop, providing fast and quantitative raw materials for the peeling machine 3. Steam peeling machine

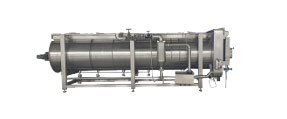

3. Steam peeling machine

Function: Use high-temperature and high-pressure steam to quickly peel potatoes

Features: Equipped with an automatic weighing system; The tank door closing detection system ensures that steam enters only after the tank door is closed, avoiding the occurrence of safety accidents. The key components such as steam seals, rotary valves, and steam valves are all made of foreign technology and are durable. Fully automatic control, adjustable peeling speed.

Production capacity: 8T/H

Reaction tank: 18MM thick SUS304, capacity 500L

Power: 5KW

Fully automatic control, adjustable peeling speed

4. Exhaust system (buffer tank, pipeline, and muffler)

Function: Used for instantaneous release and noise reduction of high-pressure steam in the peeling machine, equipped with an automatic spray pressure reducing device. 5. Separate the steam drum

5. Separate the steam drum

Function: Cache continuous and stable high-pressure steam for the peeling machine

Volume: 3.2m ³ Design pressure 2.2Mpa

6. Spiral Twisted Dragon

Function: Cache and upgrade the product to the brush peeling machine

Size: 4100 * 940 * 2100

Power: 4KW 7. Brush and leather brushing machine (with screw)

7. Brush and leather brushing machine (with screw)

Function: Thoroughly remove the remaining skin on the surface of potatoes and clean them with water;

Features: Equipped with dual motor belt drive, fast speed, low noise, thorough peeling; Equipped with a spiral screw and automatic discharge.

Size: 3200 * 1580 * 2250mm

Production capacity: 5T/H

Power: 5.15KW

Wear resistant wool roller: diameter 160mm, variable frequency speed regulation

8. Drum brush leather machine

Function: Further clean the surface of potatoes;

Size: 3400 * 1200 * 1730

Production capacity: 5T/H

Power: 0.75KW

Variable frequency speed regulation;

9. Platform

Function: Equipped with guardrails and ladders for cleaning and maintaining equipment

Frame material: 50 * 50 * 2mm square tube+crocodile plate SUS304

III. Selection and cutting system 1. Water jet cutting machine

1. Water jet cutting machine

Function: Equipped with an automatic tool changing system and a flexible adjustment guide, it can effectively ensure vertical cutting, high quality, and no feathering through various potato specifications;

Size: 14000 * 1500 * 3000mm, size can be customized according to user's on-site needs

Production capacity: 6T/H

Power: 23KW

Efficient material conveying pump;

Quick insert combination blade, imported from Europe, available in various sizes ranging from 7-10mm;

Flexible adjustment guide.

1.1. Cyclone tank

Function: Provide stable and sufficient water supply for the waterjet, and precipitate and collect starch in the water.

Capacity: 2.5 cubic meters

1.2. Starch collection system

Function: Includes automatic starch collection and water utilization system. And collect and drain the starch in the water, and recycle the reclaimed water. 2. Thin film sorting machine

2. Thin film sorting machine

Function: The gap between the rollers can be adjusted to 2-8mm, allowing for quick screening of non-conforming sheets.

Size: 1000 * 1300 * 2400

Production capacity: 5T/H

Power: 0.75KW

The thickness of 2-8mm can be manually adjusted; 3. Short strip sorting machine

3. Short strip sorting machine

Function: Quickly filter short bars smaller than 40mm;

Size: 3600 * 1400 * 3200

Output: 4.5T/H,

Double layer screen, can quickly replace different mesh screens according to different product requirements.

Power: 0.5KW

4. Platform

Function: Equipped with guardrails and ladders, for cleaning and maintaining equipment

Frame material: 50 * 50 * 2mm square tube+crocodile plate SUS304

IV. Blanching and color protection system 1. First stage spiral blanching machine (with Ferris discharge wheel)

1. First stage spiral blanching machine (with Ferris discharge wheel)

Function: Perform high-temperature short-term blanching on the product to gelatinize the starch, produce a gritty texture and taste, and prevent product browning; Spiral design ensures even blanching and consistent quality; Steam heating, multi-stage automatic temperature control, variable frequency speed regulation, timed discharge;

Power: 5KW

Size: 4000 * 1970 * 230mm

Water circulation pump;

Ferris discharge wheel, to prevent breakage and leakage to the greatest extent possible; 2. Two stage spiral blanching machine (with Ferris discharge wheel)

2. Two stage spiral blanching machine (with Ferris discharge wheel)

Function: Low temperature long-term blanching of products to fully gelatinize starch and dilute reducing sugars; Spiral design ensures even blanching and consistent quality; Steam heating, multi-stage automatic temperature control, variable frequency speed regulation, timed discharge;

Power: 7KW

Size: 6900 * 1970 * 2200mm

Water circulation pump;

Ferris discharge wheel, to prevent breakage and leakage to the greatest extent possible;

3. Color protection system (material pump, mixing tank, pipeline)

Function: Adjust SAPP for color protection, fully enclosed pipeline transportation, avoid contact between French fries and air during the color protection process, and ensure that French fries do not change color for 24 months;

Production capacity: 6T/H

Power: 11KW

Variable frequency speed regulation;

4. Platform

Function: Equipped with guardrails and ladders, for cleaning and maintaining equipment

Frame material: 50 * 50 * 2mm square tube+crocodile plate SUS304

V. Drying system 1. Vibration fabric machine

1. Vibration fabric machine

Function: Use vibrating screen to quickly and evenly distribute fabric;

Material: SUS304 board 6mm

Power: 0.5KW

Size: 3200 * 1000 * 3000mm 2. Section continuous dryer

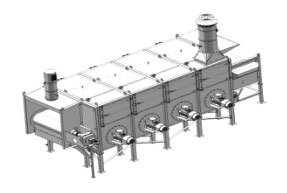

2. Section continuous dryer

Function: Drying and awakening the French fries, removing excess moisture while evenly distributing it inside, resulting in a good taste and texture. Independent temperature and humidity control in Zone 5 to achieve optimal drying effect;

Power: 60KW

Heating method: steam+heat exchanger

Size: 7000 * 3600 * 4500mm

Two stage continuous dryer

Function: Drying and awakening the French fries, removing excess moisture while evenly distributing it inside, resulting in a good taste and texture.

Power: 60KW

Heating method: steam+heat exchanger

Size: 7000 * 3600 * 4500mm 3. Aggregate mesh belt

3. Aggregate mesh belt

Function: Collect the logistics from the dryer and transfer it to the vibration machine.

4. Vibration fabric machine

Function: Use vibrating screen to quickly and evenly distribute fabric;

Power: 0.5KW

Size: 2000 * 1400 * 1000mm

5. Awakening conveyor

Function: Awaken the product and transport it to the frying machine;

Mesh belt width: 500mm

Adjustable speed;

Power: 1.5KW

6. Platform

Function: Equipped with guardrails and ladders for cleaning and maintaining equipment

Frame material: 50 * 50 * 2mm square tube+crocodile plate SUS304

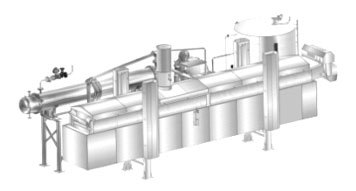

VI. Frying system 1. Steam heated continuous fryer

1. Steam heated continuous fryer

Function: Using Dutch technology, specifically designed for deep frying French fries, with a reasonable and smooth oil circulation, precise temperature control in multiple temperature zones, and energy saving and high efficiency. Fry French fries quickly at high temperatures to ensure optimal color, crispness, and texture;

Mesh belt size: 8500 * 900mm

Heating method: Steam

Production: 3 tons/h

Automatic oil level control system

Automatic temperature control system

1.1. Slag remover

Function: Filter and remove potato chips debris. 1.2. Heat exchanger

1.2. Heat exchanger

Function: Transfer steam heat energy from the shell side to the vegetable oil in the tube side.

Design pressure: 2.5Mpa

Material: SUS304

Heat exchange area: 70 square meters

Insulation layer: 50mm

1.3. Oil storage tank

Function: Oil storage for frying machine with steam heating.

Capacity: 5 cubic meters

Material: SUS304 3mm board

Insulation layer: 50mm

2. Vibration oiling machine

Function: Use vibrating screen for rapid oil removal;

Power: 0.5KW

Size: 2000 * 1400 * 3100mm